MDPE Pipes for Gas Conveyance (IS 14885:2022)

At Natraj Pipes, our MDPE pipes, certified under IS 14885:2022, are meticulously engineered for the secure and efficient distribution of natural gas, LPG, and other industrial gases. Made from third-generation bimodal, cadmium-free Medium Density Polyethylene, these pipes are corrosion-resistant and lightweight. Our PE 80 and PE 100 pipes are distinctively colored yellow and orange, respectively, for easy identification and to meet global safety and performance standards in gas conveyance systems.

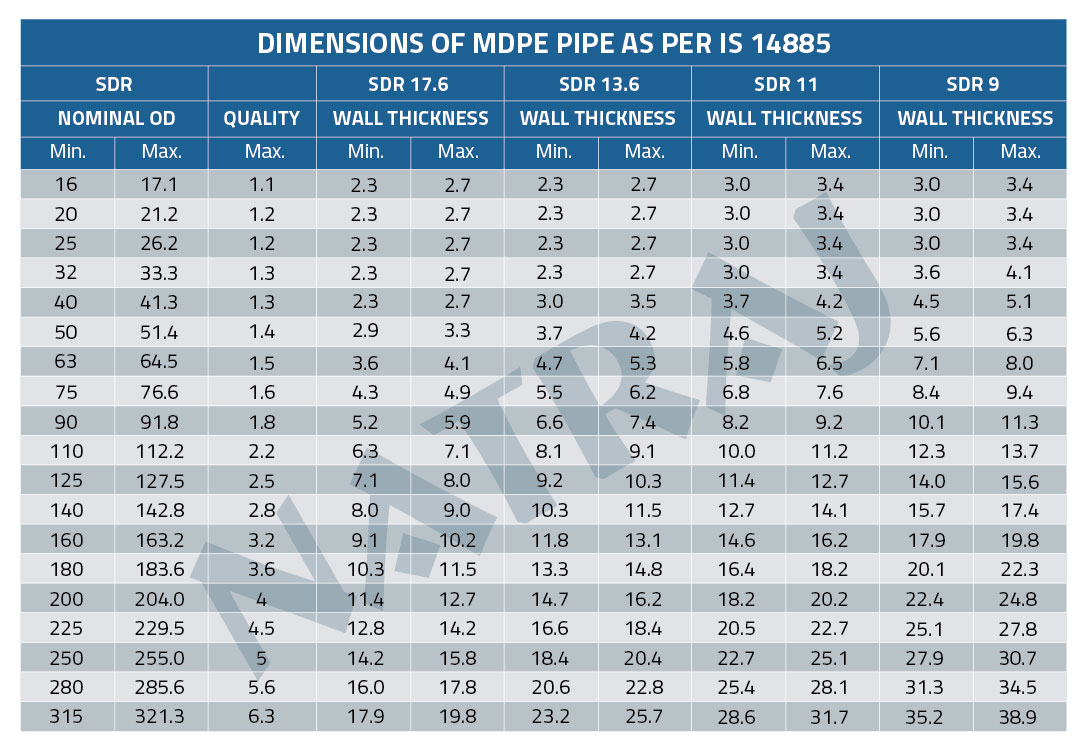

Our pipes range from 16mm to 315mm in diameter, accommodating diverse needs in gas distribution from residential to industrial applications. Each pipe is meticulously manufactured to meet the rigorous specifications of IS 14885:2022 and is also available for supply as per ISO 4437 standards.

- Our MDPE pipes are ideal for distributing gas across diverse residential, commercial, and industrial networks, ensuring reliable supply whether in densely populated urban areas or isolated industrial zones.

- These pipes efficiently transport biogas from production sites to energy facilities, facilitating sustainable energy initiatives.

- Utilized for extracting and conveying landfill gases, our pipes contribute to environmental cleanup and renewable energy production.

- Suitable for the transport of various gases in processing and manufacturing industries, our pipes maintain integrity even under demanding conditions.

- The quick installation process of our pipes makes them ideal for emergency infrastructure, providing essential support for public safety and disaster management.

- In hospitals and healthcare facilities, our pipes ensure a safe and continuous gas supply, where reliability can be a matter of life and death.

- They deliver essential gas feed for power generation and other utility services in power plants and utility infrastructure, supporting core infrastructure needs.

- Used in agricultural settings for greenhouse heating or operational fuel supply, our pipes enhance agricultural productivity and efficiency.

- Our pipes equip ports and maritime infrastructures with robust gas lines capable of withstanding harsh marine environments.

| Features | Advantages |

|---|---|

UV Resistant |

Material formulation includes UV inhibitors that protect the pipes from sun damage, extending their lifespan even in exposed conditions. |

Thermal Stability |

Withstands temperature variations without compromising structural integrity, ensuring reliable performance in diverse climates. |

Chemical Resistance |

Resists degradation from various chemicals and gases, enhancing the safety and durability of the pipeline system. |

Eco-Friendly |

Made from environmentally friendly materials that are recyclable, supporting sustainable construction practices. |

Colour Coding |

Pipes are color-coded (yellow for gas) to ensure easy identification and safety during installation and maintenance. |

Pressure Ratings Versatility |

Available in multiple pressure ratings to suit high and low-pressure applications, providing flexible solutions for different gas conveyance needs. |

Odorant Resistance |

Resistant to the long-term effects of odorants used in gas systems, which prevents degradation and ensures durability. |

Hydrostatic Strength |

Possesses high hydrostatic strength to withstand internal pressures without bursting, ensuring operational reliability. |

Reduced Noise Transmission |

Quieter operation compared to metal pipes, minimizing noise when gas flows under pressure. |

Low Thermal Conductivity |

Offers insulation properties that reduce energy loss, improving the efficiency of heated gas transport. |