COMPREHENSIVE QUALITY CONTROL

At Natraj Pipes, quality assurance is integral to our operations. Our advanced laboratory, certified by the Bureau of Indian Standards (BIS) and CIPET, Haldia, ensures rigorous quality assurance across our entire range of piping systems. Outfitted with the latest testing technologies, our lab ensures each pipe not only meets industry standards but also surpasses our stringent internal benchmarks. Under the vigilant supervision of our quality assurance team, we ensure that our products consistently embody our commitment to excellence. This dual approach of in-house and independent testing ensures our products consistently meet the highest quality standards before they reach our customers.

Advanced Testing Facilities

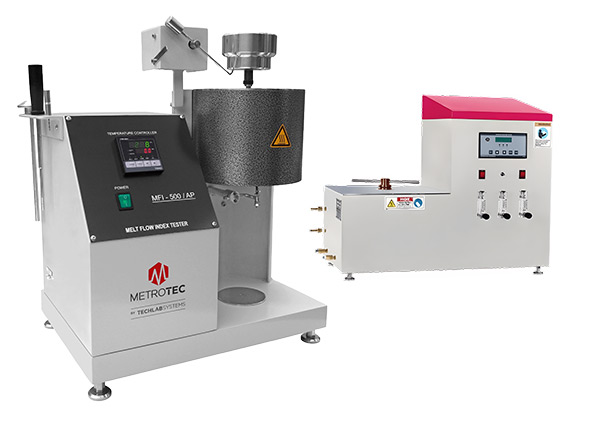

Raw Material Testing We begin with stringent raw material assessments to ensure all inputs adhere to high-quality standards. Using high-end testing instruments, we check the Melt Flow Index (MFI), Tensile Strength, Density, and Oxidation Induction Time (OIT) to ensure they meet their required minimum specifications, optimizing performance.

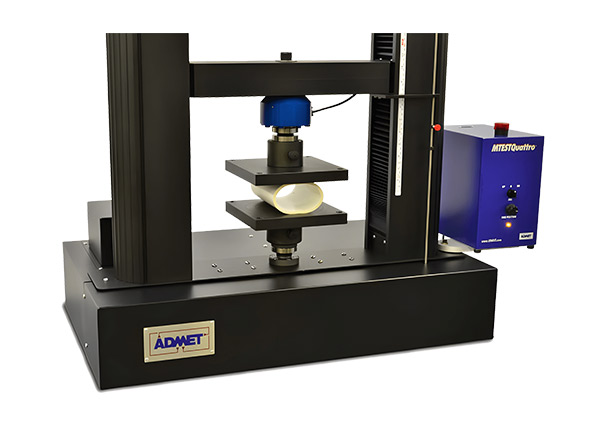

Performance Testing After clearing dimensional tests, pipes undergo comprehensive performance tests, including pressure testing, impact resistance, and flexibility assessments, to ensure robustness under diverse environmental conditions.

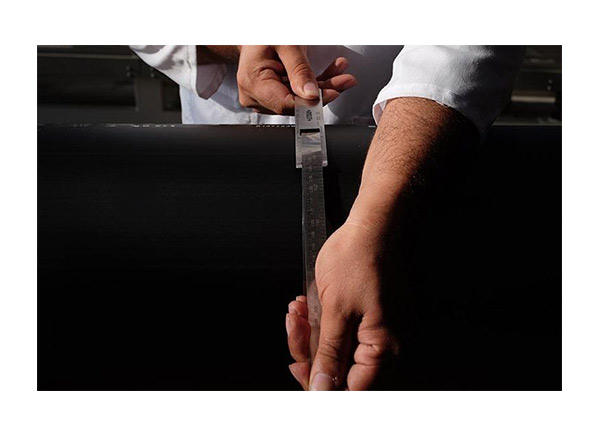

Dimensional AccuracyRegular dimensional checks are performed on each batch of pipes extruded, assessing diameter, wall thickness, and ovality to guarantee adherence to precise specifications.

UV Resistance Test Assesses both uPVC and PE pipes’ stability and durability when exposed to UV radiation, preventing degradation from sunlight exposure.

Resistance to Deformation under Load TestMeasures the ability of both uPVC and PE pipes to withstand physical loads without deforming, essential for structural integrity and longevity.

ADDITIONAL uPVC SPECIFIC TESTS

Vicat Softening Temperature Test Determines the temperature at which the material begins to soften, critical for applications in varying thermal conditions.

Thermal Stability Test Confirms that the pipes maintain their properties and functionality across a range of environmental temperatures.

ADDITIONAL PE SPECIFIC TESTS

Environmental Stress Cracking Resistance (ESCR) ESCR testing is crucial to determine how our pipes tolerate environmental stresses, thus ensuring their durability and longevity.

Heat Reversion Testing We conduct heat reversion tests to evaluate how temperature fluctuations affect the pipes' stability and structural integrity.

CONTINUAL MONITORING AND IMPROVEMENTS

Batch Testing Each production batch is meticulously tested to ensure uniform quality and early detection of any discrepancies.

Continuous Improvement Insights from ongoing testing fuel our continuous improvement protocols, driving enhancements in product quality and performance.

Certifications and Standards Compliance

Our products meet stringent international and national standards, including ISO 9001:2015. Our uPVC products adhere to IS 4985:2021, IS 12818:2010, IS 13592:2013, IS 14182:1994, and ASTM D1785, ensuring they meet precise specifications and quality benchmarks. Our PE products comply with IS 4984, IS 14151 (Parts 1 & 2), IS 14333, IS 14885, and other relevant guidelines for plastic piping systems.