MANUFACTURING & PROCESS EXCELLENCE

Zero-Defect Manufacturing Approach

At Natraj Pipes, our commitment to quality is absolute. Operating with a Zero Defects principle, we have transformed our manufacturing processes to consistently surpass the highest quality standards. By automating key inline processes and using CNC machines for precision threading of uPVC pipes, we significantly reduce potential defects, enhancing both product integrity and performance.

STATE-OF-THE-ART FACILITY

Raw Material Handling and Preparation

Automated Feeding Systems We utilize automated and computer-controlled systems to precisely measure and mix PVC resin and additives, ensuring consistent formulation and uniform quality across all batches.

Extrusion Die Design and Optimization

Computer-Aided Design (CAD) Our extrusion dies are designed and fine-tuned using advanced CAD software, allowing for precise control over pipe dimensions and wall thickness.

Die Swell Optimization We adjust die dimensions to compensate for material expansion post-extrusion, ensuring that the final product consistently meets strict specifications.

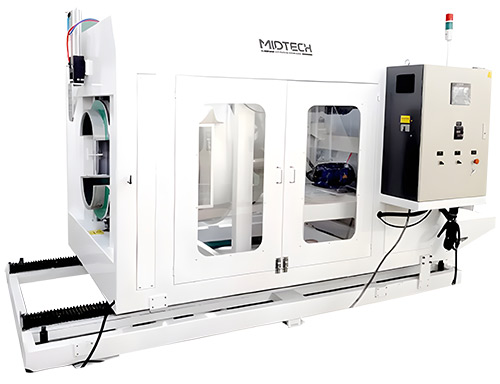

Advanced Production Technology

Our facilities feature the latest twin-screw extruders equipped with cutting-edge German technology, specifically designed for uPVC pipe manufacturing. This equipment is pivotal in our production capabilities:

High-Quality Plasticizing Capacity Our custom-designed screw barrels are engineered to guarantee uniform material consistency, crucial for maintaining the highest quality standards. This ensures that our pipes meet rigorous quality benchmarks consistently across batches, with enhanced resistance to environmental stresses and mechanical wear.

Higher Operating Speeds We have upgraded our machinery to operate at increased speeds, significantly boosting our production capacity. This enhancement allows us to swiftly meet large-scale orders and respond promptly to fluctuating market demands, ensuring timely delivery without compromising on quality.

Precisely Controlled Processing Parameters Our production process is governed by tightly regulated parameters, which are continuously monitored and adjusted by advanced control systems. This meticulous attention to detail ensuresthat each pipe meets stringent quality and performance specifications, reinforcing our reputation for reliability and customer trust.

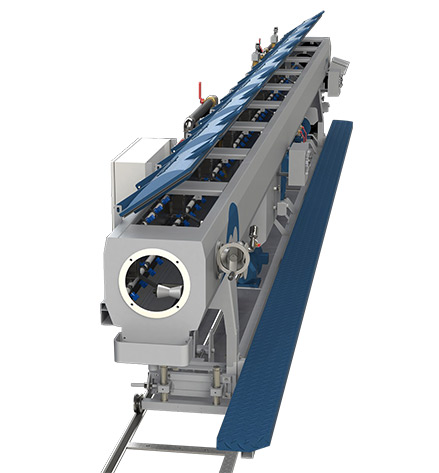

Advanced Calibration and Cooling Systems

Our top-tier vacuum calibration and rapid cooling systems are crucial in defining the pipe's precise dimensions with impeccable accuracy. These systems play a key role in our manufacturing process:

Precision Calibration Utilizing the latest in calibration technology, our pipes are shaped with precision to meet strict dimensional tolerances, ensuring consistent performance and compatibility with existing systems and fittings.

Rapid and Uniform Cooling Our cooling systems are designed to quickly and uniformly cool the pipes, preventing any warping or deformities that can occur with uneven temperature distribution. This ensures that each pipe maintains its structural integrity and exact specifications from the moment it leaves the production line.

Material Quality and Selection

Raw Materials At Natraj Pipes, we are committed to using only the highest quality raw materials to ensure the performance and durability of our products. Our uPVC pipes are manufactured using premium PVC resin, compliant with IS 17658:2021, to guarantee products free from impurities and with optimal formulation. This commitment ensures our uPVC pipes offer superior strength, durability, and resistance to UV radiation, chemicals, and physical impacts.

Simultaneously, our HDPE and MDPE pipes utilize high-grade polyethylene materials such as PE63, PE80, and PE100. These materials are selected for their exceptional strength, flexibility, and resilience to environmental stressors, making them ideal for a variety of demanding applications.

uPVC Additives Our uPVC pipes are enhanced with premium, lead-free stabilizers, impact modifiers, and lubricants. These high-quality additives improve the material's properties and facilitate processing, contributing to the superior quality and extended longevity of our products while ensuring they are environmentally safe and non-toxic.

PE Additives For our HDPE and MDPE pipes, we incorporate specialized performance enhancers like UV stabilizers, antioxidants, and heat stabilizers. These additives are crucial in enhancing the thermal and oxidative stability of our pipes, allowing them to perform reliably in various environmental conditions and ensuring a prolonged service life.