Optimal Jointing Methods for PE Piping Systems

The integrity and functionality of PE piping systems depends significantly on the chosen jointing methods. This guide outlines the best practices for jointing PE pipes using techniques compatible with our high-quality products, aimed at achieving superior durability and reliability in various applications.

KEY JOINTING METHODS

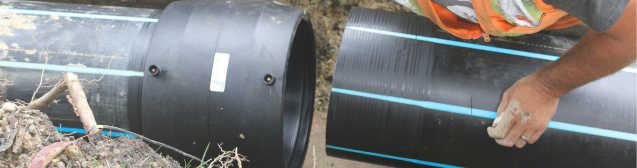

Butt Fusion: A preferred method for creating strong and seamless joints, butt fusion involves heating the pipe ends before pressing them together. This process forms a joint with strength equivalent to the pipe itself, making it ideal for high-pressure and demanding environments..

Electro Fusion: Electro fusion is essential for precise jointing, using electrically heated fittings that meld with the pipe to create a robust connection. This method is particularly useful for complex installations or repairs where precision is paramount.

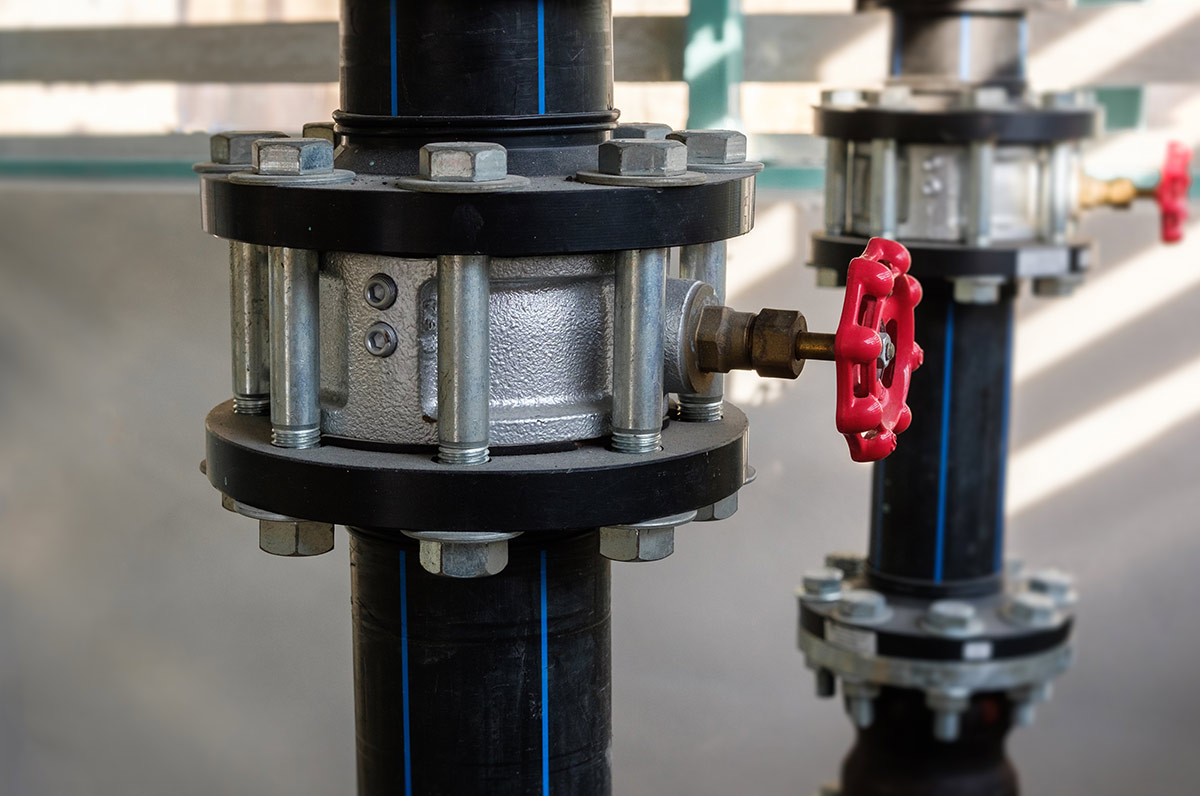

Flange Jointing: Flange jointing is utilized where modular assembly or frequent maintenance access is required. This technique involves attaching flanges to pipe ends and securing them with bolts, allowing for easy disassembly and reassembly.

OTHER EFFECTIVE TECHNIQUES

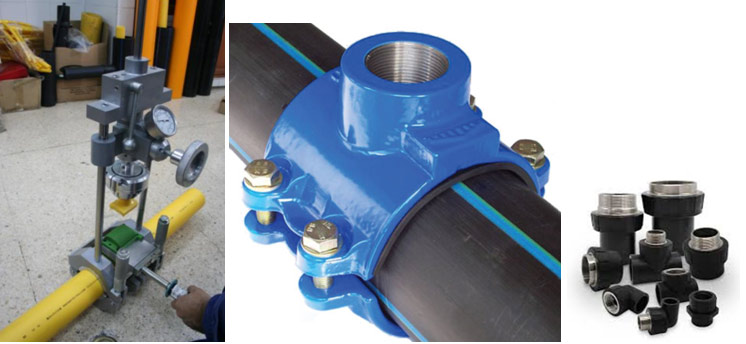

Additional jointing techniques such as socket fusion, saddle fusion, and the use of mechanical fittings provide further flexibility and adaptability for specific conditions and requirements. Each method is designed to ensure secure and reliable installations across a variety of settings.

QUALITY ASSURANCE

Our PE pipes are manufactured to be fully compatible with these jointing techniques, ensuring they can be integrated effectively into any piping system. We ensure every pipe adheres to strict quality standards, guaranteeing optimal performance and long-term reliability.